Quality assurance

Ensure quality.

With cleanliness, order and modern tools.

Quality through constant improvements.

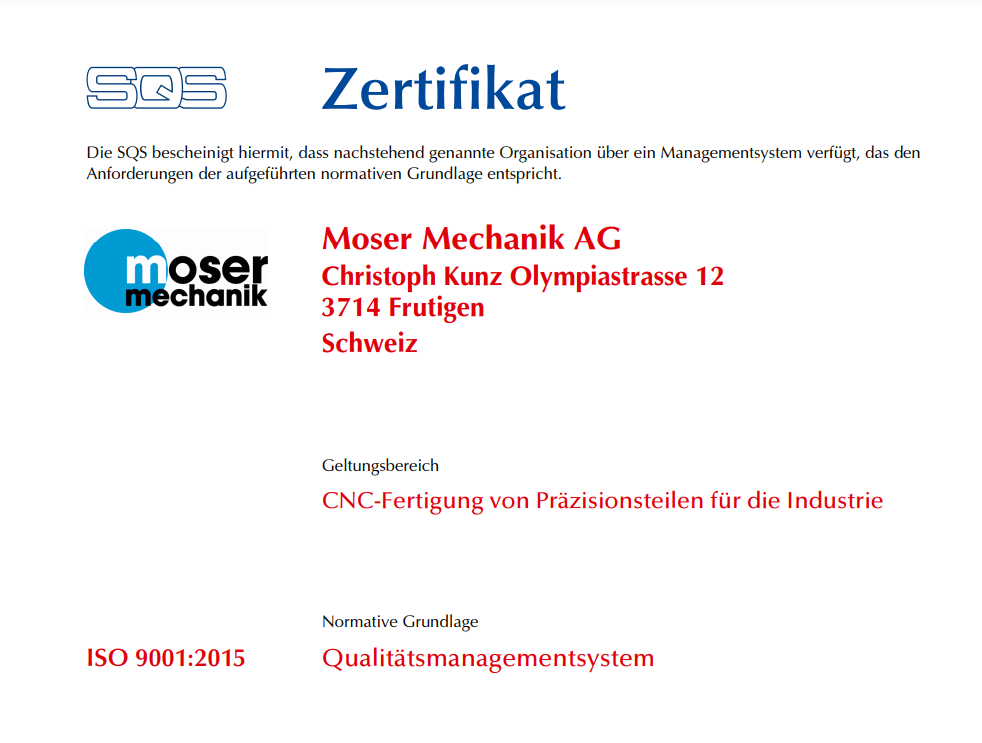

We have been fully certified to ISO 9001 since 1997 and in March 2017 the company was successfully certified to the updated 9001:2015 standard.

On April 6, 2023, we were once again able to successfully complete a recertification audit:2023-2026_SQS